The history of radiant barriers date back further than most people think. Since the 1920's, people have used reflective insulation in homes and commercial buildings to reduce energy costs.

Commercially Produced Radiant Barrier

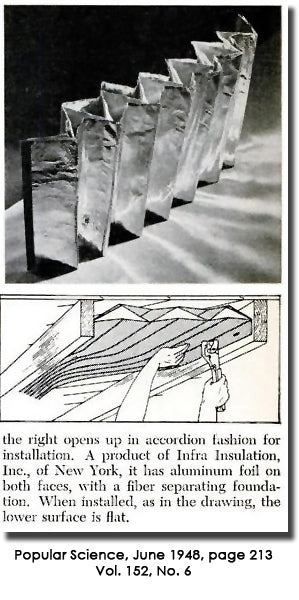

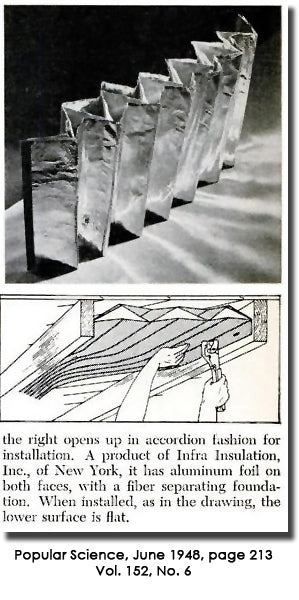

In 1945, Alexander Schwartz developed INFRA Insulation, a reflective insulation product, for Infra Insulation, Inc. in New York City. Its purpose was to keep homes and buildings cool in the summer and retain warmth in the winter. Architects and builders quickly adopted this solution for constructing more energy-efficient homes. Infra Insulation, Inc. soon became the leading producer of reflective foil insulation.

INFRA Insulation started selling an accordion-style product in the 1950s, which people could easily install with a staple gun. Pictures of women installing the radiant barrier in their homes were used in newspaper ads. By the early 1960s, people had installed millions of square feet of this insulation in various structures.

Unfortunately, a negative ruling from the Federal Trade Commission (FTC) against Infra Insulation Inc. and the sudden death of Schwartz in the early 1960s led to the complete removal of INFRA Insulation radiant barrier from the market by 1965, resulting in the closure of the business.

NASA Uses Radiant Barrier

In the mid-1950s, Clark E. Beck, PE, at Wright-Patterson Air Force Base, played a key role in developing reflective insulation technology for NASA and the space program. At that time, he couldn't have anticipated the diverse uses this insulation material would eventually have.

NASA aimed to shield astronauts during spacewalks from extreme temperature swings ranging from -273 degrees Celsius to +238 degrees Celsius. Traditional insulation would have required a cumbersome seven-foot thick layer on the spacesuit, which was impractical. Instead, NASA turned to reflective technology, utilizing aluminum foil to address the challenge. The foil reflected the astronauts' body heat, keeping them warm, and also reflected the sun's intense radiation away to keep them cool.

The reflective surface blocked more than 95 percent of radiant heat from entering the space suit keeping the astronauts comfortable.

NASA has been using radiant barrier technology since the Gemini and Apollo missions. This insulation played a crucial role in the environment control system, enabling Apollo astronauts to work comfortably inside the Command Module wearing short sleeves instead of bulky space suits. After the Gemini and Apollo missions, radiant barrier technology became a standard feature on almost all spacecraft, even on unmanned missions where instruments needed thermal protection.

NASA has been using radiant barrier technology since the Gemini and Apollo missions. This insulation played a crucial role in the environment control system, enabling Apollo astronauts to work comfortably inside the Command Module wearing short sleeves instead of bulky space suits. After the Gemini and Apollo missions, radiant barrier technology became a standard feature on almost all spacecraft, even on unmanned missions where instruments needed thermal protection.

While there is no official NASA radiant barrier, the products today are similar and even better than those used by the aeronautical program.

Reflective Insulation Enters the Consumer Market

After Infra Insulation, Inc. closed down, several companies started creating their own reflective insulation products. These came in different forms, including bubble layers, single-sided aluminum Kraft paper-backed barriers, aluminum-faced fiberglass, and even aluminum-faced cardboard products. However, the radiant barrier industry faced challenges because of established corporate interests in traditional mass insulation like fiberglass, cellulose, and rock wool.

Companies producing traditional insulation saw the rising popularity of radiant barriers as a significant threat to their products. They tried to impede the growth of radiant barriers through lobbyists and industry association campaigns. The traditional insulation industry invested heavily in marketing and educating consumers about the importance of R-Value rated insulation products. Since radiant barriers work differently and don't have R-Values, consumers were influenced away from choosing reflective radiant barrier insulation.

Despite these challenges, architects and engineers became increasingly interested in radiant barriers and reflective insulation. They recognized the effectiveness of these products and started including them in their building and design plans.

Confidence and Popularity of Radiant Barriers Grow

Thanks to the backing of architects and engineers, news about the advantages of radiant barrier products spread rapidly in the insulation industry. To validate the claims made by builders and others regarding the benefits of radiant barrier and reflective insulation products, prominent testing facilities and research organizations conducted their own studies. Testing facilities at the Department of Energy, Oak Ridge National Laboratory, Florida Solar Energy Center, and Texas A&M University have demonstrated the significant advantages offered by radiant barriers.

Today's Radiant Barrier

Radiant barrier history dates back many decades and gaining acceptance and popularity was a challenging journey.

Energy-efficient engineers, architects, builders, and the reflective insulation industry today widely recognize radiant barriers as a cost-effective method to permanently lower utility bills and enhance the comfort of homes and buildings.